KARL SCHMIDT SPEDITION

The SCHMIDT family business has developed into a leading service provider for bulk logistics throughout Europe. 2,500 employees at 49 locations world-wide provide extensive one-source service for our customers and clients when transporting, storing and handling bulk goods. In addition, the SCHMIDT Group is active in the construction of logistics facilities for free-flowing bulk goods. Every day, the SCHMIDT Group processes more than 1000 transport orders. Plus stock orders and customer-specific specialty orders. Our very own state-of-the-art freight-forwarding software supports users from various participating fields.

Years of experience

Worldwide locations

Employees

Orders/day

SERVICES

TRANSPORT

Transport services by silo trucks and containers are the core business of SCHMIDT Heilbronn.

LEARN MORE

IMPORT & EXPORT

SCHMIDT is offering full-service from one source for all your import and export shipments.

LEARN MORE

LOGISTICS SOLUTIONS

As your full-service logistics partner, SCHMIDT designs customized, tailor-made solutions.

LEARN MORE

WAREHOUSING FOR BULK GOODS

The SCHMIDT Group operates the largest network of logistics centers for the European plastics bulk industry.

LEARN MORE

PRODUKTHANDLING

The SCHMIDT Group offers complete supply chain options from the production line to the consignee.

LEARN MORE

TANK CLEANING

The inside cleaning of the tank unit is an essential part of the quality chain for bulk transports.

LEARN MORE

MAINTENANCE & REPAIR

the SCHMIDT-Group process over repair workshops at numerous locations.

LEARN MORE

INFORMATION TECHNOLOGY

Our own state-of-the-art forwarding software supports all users from various areas interlinked.

LEARN MORE

SPECIAL SERVICES

OPTICAL SORTING

Recovery of the highest purity level in bulk goods not mixed according to specifications or intermixed with foreign particles.

LEARN MORE

MOBILE BELT THROWER

With our mobile belt thrower we execute rear loadings for all current types of 20‘ and 40‘ maritime containers.

LEARN MORE

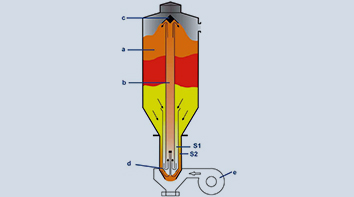

HOMOGENIZING

Mixing, homogenization of various granulate quantities (e.g. irregular product batches) to achieve uniform qualities

LEARN MORE

MECHANICAL FILTRATION

Separation of different granular or powder fractions (e.g. contaminants, different granule sizes, spelt)

LEARN MORE

ELEKTRONIC METAL SEPARATION

Specifically for separating all magnetic and non-magnetic metals (including metal enclosures) from particle sizes of 1 mm.

LEARN MORE

PRODUCT DRYING

Drying of wet granular products (surface moisture)

LEARN MORE

VACUUM TANKER

Evacuation from customer silo or tankers involved in accidents

LEARN MORE

DEDUSTING

Separation of dust and angel hair from granulate products achieving dust residue values of 30 ppm max.

LEARN MORE